As we learned in part one of the series of articles "How to soundproof your home," there are two main factors that determine the degree of sound insulation in a room, namely the sound insulation index of the room's elements and the passage of sound through bypass routes.

In the second part of this series of articles, we will tell you about the two main types of systems in building acoustics and which properties of materials and systems are decisive and extremely important for the sound insulation index, and which ones are not essential.

Basic concepts

Before distinguishing between the different types of systems, it is important to introduce some simple terminology. All materials that have an open porous or fibrous structure and through which air can pass are called air-permeable. These include all mineral wools, polyester wools, fabrics, and foam (polyurethane or melamine foam). All other popular building materials, such as ceramics, concrete, gypsum cardboard panels, wooden panels, bitumen or polymer membranes, expanded or extruded polystyrene (EPS and XPS), metal sheets, and others, will be referred to as dense materials.

Which is the first system?

The first scientific research in the field of sound insulation began in the 1940s with one of the first publications by German scientist Professor Cremer in 1942. He laid the foundations for the theory of single-leaf systems for sound insulation. This is the first sound insulation system that we will present to you. You may wonder why we call it a single-leaf system. The answer is that in building acoustics, we consider all systems consisting of only solid materials that are not separated by an air gap or air-permeable material as single-leaf systems. There are many examples:

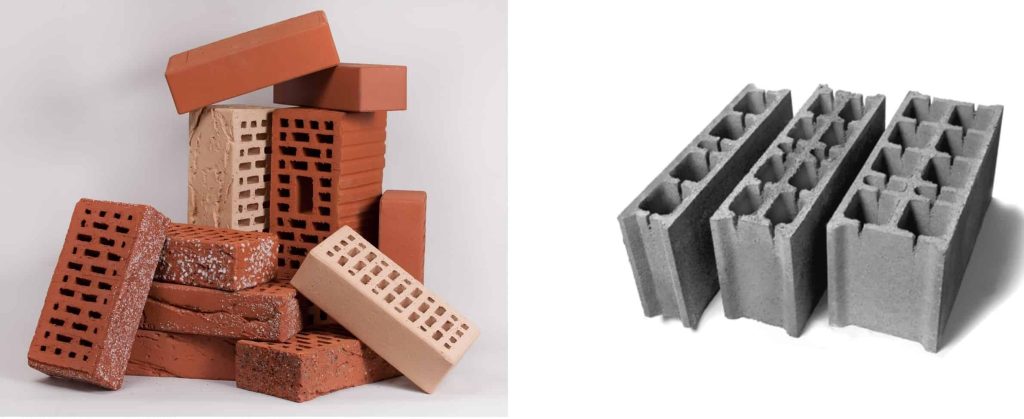

- Brickwork with plaster, consisting of hollow ceramic blocks bonded with mortar and plastered on both sides with gypsum plaster

- Glass partition walls with single glass

- Concrete slabs with screed and floor covering

- Solid wood doors made of solid wood and glued MDF

- Brickwork with stone or ceramic cladding

- Roof structure made of wooden cladding, bitumen membrane for waterproofing and tiles

In general, we consider all systems made of solid materials that are bonded or fastened together as single-layer systems.

Are there different types of single-sheet materials?

Before understanding which properties of materials in single-sheet systems determine their degree of sound insulation, we must make a very important distinction. We will divide sheet systems into two types:

- Sheet systems with homogeneous isotropic materials (materials that have the same properties in all directions) Examples of such materials are: concrete, plasterboard, lime and cement mixtures, aerated concrete bricks, bitumen membranes, and others.

- Sheet systems with non-homogeneous orthotropic materials (materials that have different properties in different directions). Examples include wood, hollow ceramic bricks, and concrete bricks.

What does the sound insulation graph for homogeneous isotropic materials look like?

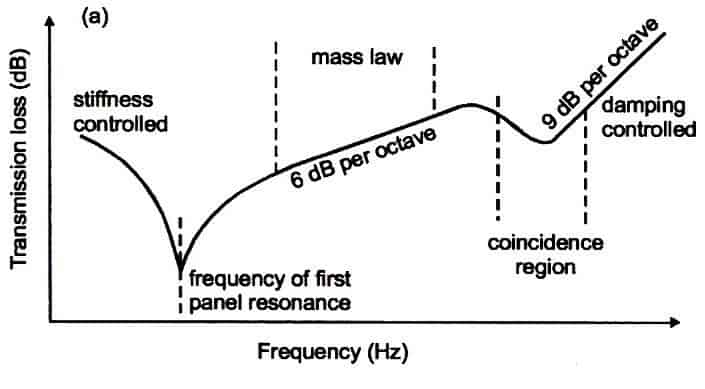

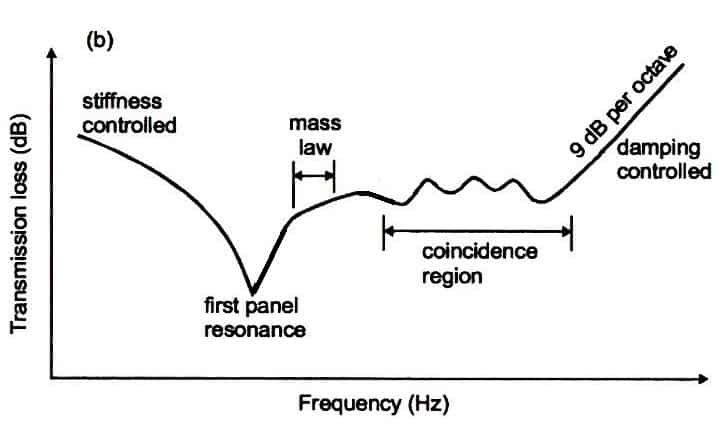

In the case of homogeneous isotopic systems, the typical sound loss graph looks like this:

Engineering Noise Control: Theory and Practice, 3th Edition by Colin H. Hansen David A. Bies

There are five different zones that determine the degree of sound insulation.

Zone one, also called "Stiffness controlled," is defined by the bending strength of the system, which is a function of its elasticity and dimensions (length, height, and thickness). An interesting fact is that if we compare the sound insulation of a metal sheet with a thickness of 0.6 mm and dimensions of 2.00/2.00 m and the same sheet, but with dimensions of 0.20/0.20 m, the results will be radically different, especially in zone one. The smaller size will show much higher values than the larger size because the bending strength of the sheet with dimensions 0.20/0.20 m is much greater. The bending strength can be increased by forming this sheet material into LT sheet metal (bending into a specific profile).

Zone two – the resonance frequency of the system. As we know, every object, building, and machine in nature has its own frequency. It is determined by the shape, strength of the material it is made of, and its dimensions. The most common example is a wine glass. It has a frequency that, if it resonates with the voice of an opera singer, would break the glass. It is the same in building systems. Each partition element has its own resonance frequency, which is determined by the dimensions, weight, and bending strength of the element. If we take the above example, the resonance frequency of the smaller metal sheet is different from that of the larger sheet.

By increasing the mass of the system, the resonance frequency decreases, thereby increasing the bending stiffness of the system and increasing the resonance frequency. When seeking good insulation, the goal is to reduce the resonance frequency below the threshold of human hearing (20Hz).

The third zone is the zone that is most affected by the weight of the system and is defined by the "mass" law, which states: With each subsequent frequency band, the sound losses of the system increase at a rate of 6dB per octave. If we double the mass of the system, we will increase the sound insulation in this zone by 6dB. To better understand this, let's look at an example.

If we have a concrete wall with a thickness of 8 cm, which weighs 192 kg/m², in order to increase the sound insulation in this area by 6 dB, we need to double the thickness. If we put a layer of bitumen membrane weighing 5 kg/m² on top of it, the sound insulation would change by 0.15 dB, which is negligible.

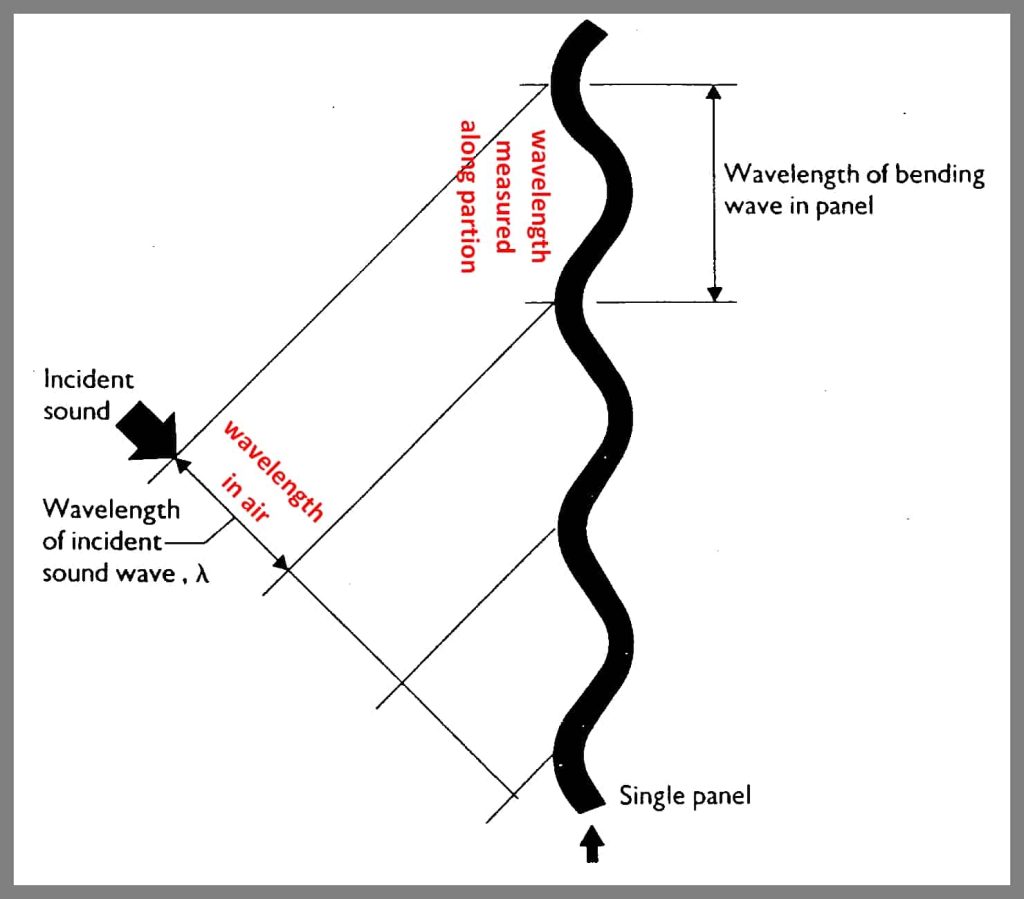

The fourth zone is the most confusing and difficult to understand. This is the frequency matching zone. Simply put, it is the lowest frequency at which the angle of incidence of the sound waves coincides with the angle of bending of the barrier caused by sound loading. The value of this frequency and the degree of resonance depend on two factors: the internal loss coefficient of the material and the bending strength. It is important to distinguish between the natural resonance frequency and the coincidence frequency. The coincidence frequency occurs most often at high frequencies and is directly related to the angle of incidence of the sound waves on the partition element.

And lastly, there is the fifth zone, which is designated for the influence of internal material losses. With increasing frequency, sound losses increase by 9dB.

What is the difference between the sound insulation graph of homogeneous isotropic systems and that of orthotropic systems?

The situation with orthotropic systems is very similar in terms of zones, but their influence is different. For example, zone three (mass law) has a much smaller frequency range than zone four (frequency matching). The graph is flat in the mid-range frequencies, which reflects a low sound insulation index.

Engineering Noise Control: Theory and Practice, 3th Edition by Colin H. Hansen David A. Bies

This is one of the reasons why single-layer brick walls with hollow bricks cannot achieve high levels of sound insulation even if their weight is doubled. The calculation models for these systems are extremely complex and involve mathematical apparatus in order to achieve accurate measurement results.

What conclusions can we draw about single-member systems?

When we want to soundproof a single-layer system, we need to pick a combo of materials that are uniform, bendy, and heavy. To make the system soundproof better by adding weight, that weight needs to be at least 50% of what's already there. With non-homogeneous materials, we cannot expect that increasing the weight will increase the sound insulation. To increase the index, we must seek to increase the bending strength in the weakest direction and increase the internal losses of the system.

What alternative system can we use for sound insulation?

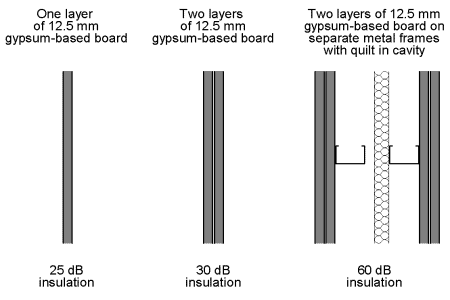

In 1949, two publications by Beranek & Work and London were issued on the subject of sound insulation of double-leaf systems, also known as double walls. All structures consisting of two single-leaf systems separated by an air gap or air-permeable material between them are defined as double-leaf systems or double walls. To help you visualize this, here are some examples of such systems:

- A partition wall made of gypsum cardboard panels. It usually consists of two layers of gypsum plasterboard with an air gap between them, which is either empty or filled with a type of insulation (even if we put three layers of gypsum plasterboard on one side or an additional membrane, we still consider it a double-layer system).

- Double masonry. Two brick masonries separated by mineral wool or air;

- Suspended ceilings. Concrete slab or wooden slab with a suspended solid ceiling made of gypsum cardboard panels;

- In front of wall linings on brick masonry. Again, regardless of the number of panels, as long as they are not tightly glued to the brickwork;

- Double-glazed windows (glass, air gap, glass);

- Glass partition walls with double glazing;

- Floor slab with dry subfloor. The dry subfloor must be made of breathable material and covered with solid panels such as plywood, gypsum fiber boards, and others.

These are just a few of the possible examples and combinations that exist in construction practice. It should be noted here that the calculation model for double-leaf systems is also applicable to multi-leaf systems, which are composed of the following principle: solid material + air-permeable material + solid material + air-permeable material + solid material, etc. The difference is that there are a greater number of resonance frequency drops.

Double-leaf systems are the most common systems we use for sound insulation in rooms. If we compare a single-leaf system with a double-leaf system based on their weights, the double-leaf system has over 6dB higher efficiency.

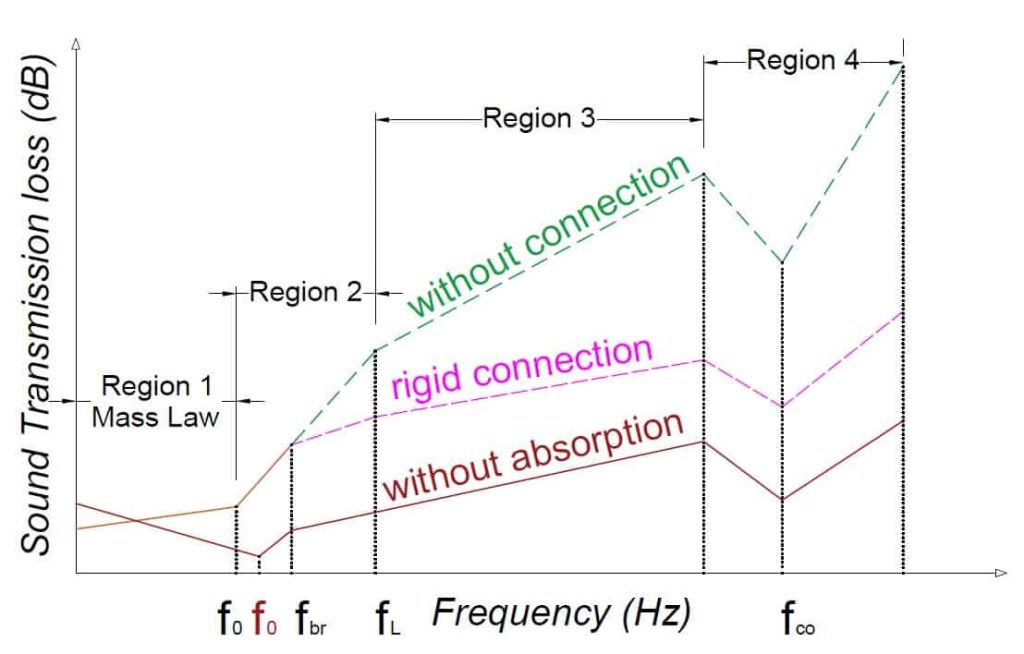

In double-leaf systems, there are four zones of change in the sound insulation curve, which are influenced by the already known factors: weight, bending strength, and internal losses. We will not go into detail about how each factor influences, because they are very similar to single-layer systems. The only important and different thing about them is that the resonance frequency is determined by the resonance frequency of the entire system. This means that the mass of the two solid materials and the distance between them are taken into account.

Here we can mention that when we talk about multi-leaf systems, more than one resonance frequency appears due to the presence of more than one air gap, which in most cases worsens sound insulation at low and medium frequencies.

The big difference and what distinguishes double-layer systems from single-layer systems is the presence of two additional factors that completely shift the graph. These are the presence of air-permeable (absorbent) material in the air gap between the two solid bodies and the type of connection between them.

According to a number of authors who have participated in numerous studies on the relationship between the sound insulation of an element and the presence and type of sound-absorbing material, we can draw the following general conclusions:

- The lack of air-permeable material in the air gap causes a shift in the resonance frequency and reduces the sound insulation of the system by at least 6dB.

- The presence of breathable material even within 20% of the air gap significantly improves the sound insulation of the system.

- The optimal thickness of breathable material is 80% of the air gap.

- The most important parameter of air-permeable material is its air resistance. It must be above 5kPa/m’. Any air-permeable material is suitable as long as it meets this condition.

- Increasing the air permeability coefficient (this is most often done by increasing the bulk weight of the material) does not increase sound insulation.

Of course, we should also mention the effect of the thickness of the air gap, which is absent in single-pane systems. Its effect in the presence of air flow is limited to low frequencies, but in the absence of such material, doubling the thickness increases the index by 3 to 6 dB. This is particularly important for double-glazed windows, where it is not possible to place air-permeable material between the panes.

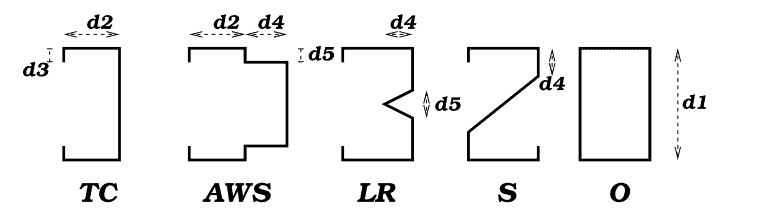

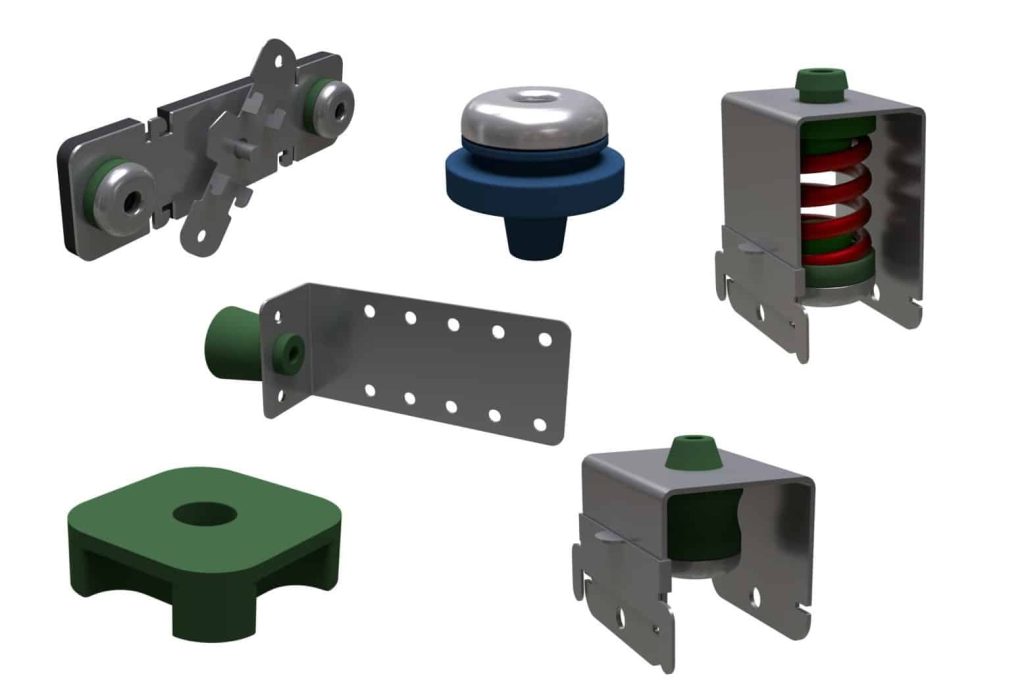

Another extremely important factor is the connection between the two solid surfaces. The graph clearly shows that its influence is in the medium and high frequencies; after the acoustic bridge frequency (fbr), the index can increase by up to 20dB if there is no such connection. Of course, in practice this is very difficult to achieve and is highly dependent on the stability of the system. Therefore, a number of companies and scientists are developing systems to reduce the influence of the "connection." What they have achieved is that the number of connections, the distances between them, and the dynamic stiffness are of paramount importance to the efficiency of sound transmission through them. To avoid going into detail, we will briefly mention examples of different elastic connections:

- Metal profiles. Depending on the type of material, wall thickness, shape, and size, its dynamic stiffness is determined. The lower it is, the more elastic the connection is, and the better the sound insulation.

- Various types of rubber and silicone mounts. Depending on the material, load, and dimensions, the dynamic stiffness can be determined again, which also determines the improvement in sound insulation. It is important to note here that the load plays a key role. If the suspension is not loaded or is loaded to its maximum, the connection is considered "rigid" and the effectiveness of the insulation is drastically reduced.

What conclusions can be drawn from two-tier systems?

When selecting such systems, for example: we install wall cladding or a suspended ceiling or a stud wall to achieve maximum efficiency, in addition to the mass and bending strength of the system, we must place a breathable material in the air gap and choose the most flexible connections (hangers) between the two structures.

From all this, what have we learned about sound insulation of elements?

To translate all this information into practical terms, we can make the following summaries:

- In the presence of concrete walls (homogeneous isotopic material), sound insulation is significantly better than that of hollow brick walls of the same thickness.

- Partition walls with higher bending strength and greater weight (concrete walls and solid ceramic brick walls) have higher insulation than walls of the same thickness but with lower strength and weight (lightweight concrete walls).

- Double walls, consisting of two planes with an air gap and insulation, have higher sound insulation than a single wall of the same thickness and weight.

- If we want to achieve the highest sound insulation values for a fixed thickness, we must use the heaviest materials possible, which are not connected to each other, and place an air-permeable material (wool, polyester, polyurethane, etc.) in the air gap. If it is not structurally possible to separate them, we must use the most elastic connections, appropriate for the load exerted on them.

Important clarification

We cannot fail to mention that these are generalised conclusions based on numerous scientific models and experiments. Much more information can be found in the research, which includes complex formulas. To date, all developed models allow for deviations of 1 to 3dB due to complex physical phenomena that cannot be covered by a single mathematical model. Nevertheless, science is adamant that these are the most important parameters that guide us in the design and construction of sound insulation systems.

What to expect from the next article?

If we recall from the previous article, the sound insulation of an element is the first of two factors that determine the degree of sound insulation of a given room. In the next part, we will learn how, in the case of a wall with a high sound insulation index, the final result for sound penetration into the room can be twice as low if we ignore the other factor, and how a 5 mm opening can deprive us of a good night's sleep.